Description

!Available gasoline version!

A band sawmill with an electric feed and cutting programmer that will greatly improve the operation of your sawmill from day one!

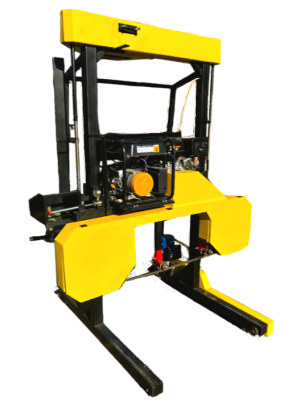

The E BIG SAM model is the bigger brother of our basic sawmill model SAM MK. Compared to its smaller version, it differs in increased maximum cutting width, while maintaining the highest possible quality and precision. The version you are currently viewing has 135 centimeters of maximum cutting width and 150 centimeters of maximum log width. The length of the tracks you will receive with the E XL is 6 meters (it is possible to extend the tracks).

This is a machine with a reliable, certified design that is second to none in its class! The stationary band sawmill is ideal for both hobbyists and professional sawmills. It is possible to configure the machine specifically to your needs. We offer shipping throughout the country and beyond. We are a global manufacturer of certified band sawmills since 2006!

Band sawmill marked with the symbol E

The prefix E in the machine model name indicates that this particular band sawmill has an electric feed and a cutting thickness programmer. A person with experience certainly knows what this means in practice. This makes work incomparably easier and faster. Cutting is smooth and vibration-free thanks to coordinated motors from the feed. With a couple of clicks we can freely set the thickness of the tops we want to obtain. When we decide to start the correctly set machine, the head, together with the saw, will make a pass along the tracks to cut the wood. After each completed cut, the RETURN button will raise the head to the memorized height and then return it to the initial position. At this point, simply press the START button again to set the bandsaw in readiness for the next cut. We offer a mode where you are not required to remove the finished wood segments between cuts. Click here to see it in the video.

What sets our band sawmill apart from the competition?

Our bandsaws are known in the woodworking industry for their simple and durable design. Thanks to this, their service does not require specialized knowledge and does not consume so much time, and as a result becomes a better investment for the company (according to the proverb that time is money). In addition, we offer the best cutting quality on the market. Our sawmills, when properly calibrated, guarantee huge savings in material. The cut that our machines make takes only 2mm of waste. This is a really good result that can result in several tops extra on a single log (depending on the thickness of the tops) compared to inferior quality bandsaws.

Anyone can operate our band sawmill efficiently. After purchasing the machine, when it is delivered to the customer, it is possible to train the person receiving it so that he can handle our bandsaw efficiently and safely. It only takes a few days of use for even the least experienced operator to make woodworking with our band saw simple and indicative.

Technical specifications:

- 11 kW motor (or 27 HP engine & generator for gasoline version)

- Electric setting of cutting thickness

- Cutting thickness programmer ISP 010

- Electric blade guide roller

- Electric feed

- Max. cutting width 135 cm

- Max. log width 150 cm

- Stable double-sided construction

- Smooth start mechanism

- Track length of 6 meters

Quality guarantee from CrissWood.

During our manufacturing process, we use materials supplied by local manufacturers, among others, which allows us to guarantee trouble-free, efficient and top quality at an affordable price.

Each band sawmill manufactured by us undergoes a series of tests. Control cuts performed on different types of wood allow us to carry out a full adjustment of components. You receive a ready-to-work machine that will easily create boards, countertops, beams or even houses!

Our sawmill has a certificate issued by the Institute of Wood Technology – Poznan: Wood Industry Products Certification Center.

Each machine comes with an Instruction Manual and EC Declaration of Conformity.

Band sawmill E Big SAM is covered by a 12 – month warranty (excluding parts subject to wear – rollers, bearings, V-belts).

Interested in purchasing Your sawmill?

If you would like to know more details or have any specific questions, then get in touch with us via the contact form or call us directly at + (48) 572 127 771.

The crisswood team will answer all your questions, including current prices. Don’t wait and get back to us today!